Understanding Below Seal Valves: Function and Applications

What is a Below Seal Valve?

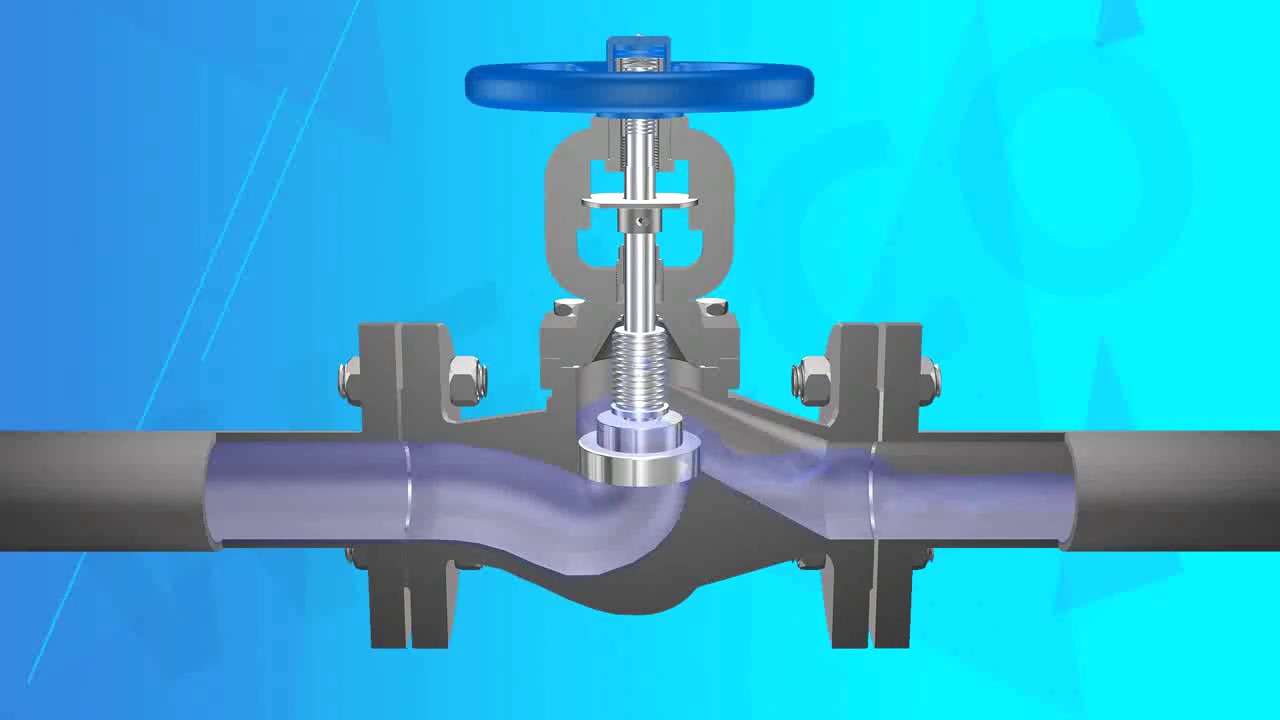

A below seal valve is a crucial component in many industrial applications, designed to ensure tight sealing and minimize leaks. These valves operate by preventing the escape of fluids or gases, which is vital in maintaining safety and efficiency in processes. The below seal design offers enhanced reliability, particularly in high-pressure systems.

How Does a Below Seal Valve Work?

Below seal valves utilize a sealing mechanism located below the valve seat, ensuring that any pressure exerted does not compromise the seal. This innovative design helps to contain substances more effectively, thereby reducing the risk of leakage. Typically made from durable materials, these valves can withstand various operational conditions, making them suitable for diverse applications.

Applications of Below Seal Valves

Below seal valves find applications across multiple industries, including oil and gas, pharmaceuticals, and water treatment. In the oil and gas sector, they play a vital role in pipelines and storage tanks, where preventing leaks is paramount. The pharmaceutical industry relies on these valves to ensure the integrity of sensitive substances. Additionally, water treatment facilities benefit from below seal valves, which help maintain strict environmental standards by containing possible contaminants.

In conclusion, understanding the role of below seal valves is essential for professionals involved in the design and operation of systems that require high reliability and safety. With proper selection and installation, these valves can greatly enhance system performance and longevity.